( As of today there has been no payment from ECOLIT for this paid editorial and the account is in excess of 90 days past due.)

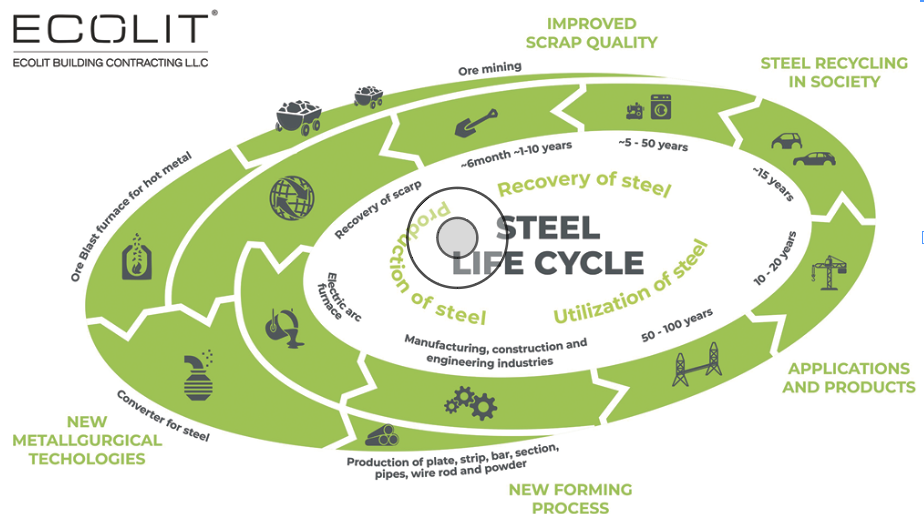

The light gauge steel frame (LGSF) industry can be a vital part of a circular economy by promoting resource efficiency and durability. By extending the lifespan of materials, it minimizes waste and environmental impact. This sustainable approach helps preserve natural resources and reduces the burden on the environment. Ecolit technology is based on these principles and makes it a crucial part of the construction process. Moreover, steel makes construction not only sustainable but also available for any projects.

Its sustainable features of the steel make the perfect choice for eco-friendly construction over any other materials. In fact, over 90% of steel can be recycled for building another project. It’s the best and easiest option for embracing modern eco technologies that have a higher rate of recycling than other common building materials such as wood or bricks.

Therefore, there is no residue to contaminate natures environment in years to come. Up to 99% has all been reused for new buildings.

Why is steel the best solution to construction in 2024?

1. Once it’s produced, it can be consistently reused.

This is a major benefit of reusing steel from buildings and structures. It can be any structural pieces that can be used without any processing. Small pieces of steel can be also melted down and used again.

In fact, around 86% of structural steel is recycled as scrap charge for furnaces, while 13% is directly used for new structures. Only 1% of steel is left to landfill or rust.

Recycling steel not only decreases production expenses by reducing the need for energy, labor, and raw materials but also eliminates the expenses related to disposing of C&D waste in landfills and acquiring virgin steel for construction purposes. Additionally, it is important to highlight that recycled steel, despite being more cost-effective, maintains a high level of quality that is well-suited for construction projects.

2. Evolving the value chain.

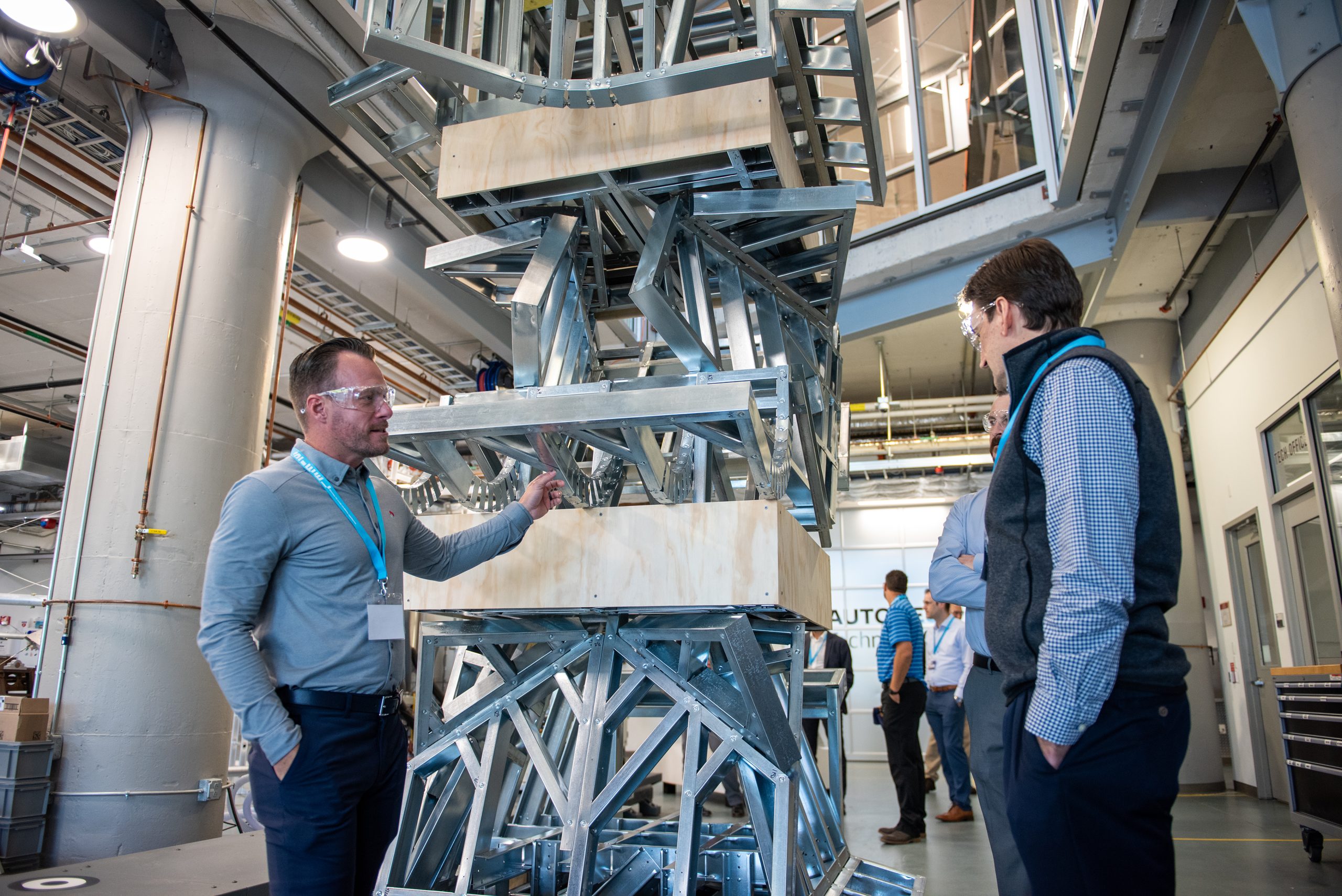

To make circular construction principles effective, business models must evolve throughout the entire value chain. It’s essential to optimize design in a circular construction approach, requiring a lot of upfront planning. Prioritizing longevity, adaptability, and the offsite approach of Design for Manufacture and Assembly is crucial. Planning for a building’s “end” from the start of the design phase is vital to enhance sustainability through Design for Disassembly, Design for Reuse, and recoverability protocols.

4. A question of time.

Buildings need to be both secure and long-lasting. Steel is an excellent choice for construction because it is not only strong and durable, but also versatile and environmentally friendly. It is lightweight and cost-effective, making it an ideal option for structural framing. With its sustainable properties, steel enhances the safety and sustainability of light steel buildings.

The recycled steel utilized in building is just as sturdy and long-lasting as its virgin counterpart. It keeps its strength even after multiple recycling processes. Additionally, this material maintains its ability to bear weight, which is crucial for structural and foundational components. Recycled steel is also resistant to corrosion, making it perfect for constructing frames and flooring in hazardous environments.

The use of sustainable materials in modern construction is crucial for protecting the environment. In addition, these building materials are also budget-friendly and long-lasting. Ecolit can help you build any building using only eco-friendly materials and make your dream house a reality.

In addition, we have a patented technology for energy-efficient, fast and affordable construction – light gauge steel framing and modified foam concrete made of natural materials.

Advantages of building a house using these sustainable materials:

1. High quality.

After being recycled, steel quality is retained. It doesn’t degrade the life-cycle of the building and its durability remains the same. Moreover, it also has a great quality and weight capacity.

2. Recycled steel is the same as the new steel.

It costs much less and requires minimal use of heavyweight equipment and lifts. In addition, it saves money on maintenance and repair due to its great durability and longevity.

3. Long lifespan.

Light gauge steel frame buildings can last up to 60 years, but in a “warm frame” environment, the design life predictions for light steel exceed 250 years.

4. No limits for construction.

Ecolit’s unique technology can be applied to any structures and buildings with any project complexity. The only limit to design of structures is the imagination of the architect.

5. No negative effects on people and the environment.

Improving the location, design, construction, operation, maintenance, and removal processes throughout the entire lifespan of a building can help minimize the harmful impacts on human health and the environment caused by buildings.

We produce our own house kits and lightweight concrete for construction high-quality buildings. Our high-tech equipment helps us be one of the top contractors who stick to sustainability and puts natures conservation as TOP priority and in first place.

The benefits of building a house

with Ecolit:

– elevated fire resistance of up to 3 hours

– high wind resistance

– raised level of sound insulation

– lowest carbon effect and sustainability

with up to with up to 99% recyclability

– durability and reliability

– fast construction timing

We apply the most modern solutions in the field of construction in more than 15 countries such as the United States, Germany, the UK, Estonia, UAE, Africa, Indonesia, Thailand and Philippines. There are currently two USA production facilities at the startup stage in California and New Jersey. We are also in the planning stages of launching a production site in Texas.

Due to expanding our production throughout the world our current mission is to supply our house kits to more countries, creating an exponential forward leap towards sustainable construction. We have already successfully built thousands of buildings using Ecolit technology, supplying countries globally where there is a huge demand in the housing market for over 10+ years.

If you’re interested in a Joint Venture (JV) partnership with us and would like to be a part of our worldwide successful journey towards sustainable construction, you can contact us any time. We will always be happy to share the details about Ecolit technology with you and answer all your questions.

Denis Lozenko

Sponsored Content