By Sharon Thatcher

Printed steel to feign the look of wood or camo is certainly not a new concept, but now Steel Dynamics (SDI) has entered the market with a game-changing new generation of technology. The steelmaker’s Butler, Indiana, team spent 2-1/2 years developing the digital designed product, Tru>Steel HD. It entered the market last September 2022, and has been making its way around the trade show circuit to expanding audience appeal.

Don Switzer, Manager of Sales, Steel Dynamics Flat Roll Group, explained that Tru>Steel HD was originally targeted to the garage door market. It has, however, caught the eye of rollformers and building contractors who see the emerging market for wall panel, both interior and exterior, an ideal fit for the specialty coil.

One customer is using it to create a log cabin effect using steel, working with SDI to incorporate a realistic look of chinking.

Their First Customer: Graber Post Buildings

Graber Post Buildings assisted SDI with selecting images that would be most receptive to the board and batten niche. “Graber Post did a fantastic job,” Switzer said. “They were actually our first Galvalume customer, and also our first painted Galvalume customer, and now they were our first digital print customer.”

It is too soon to show off a board and batten building that incorporates the new wall product, but Trent Wagler at Graber Post noted that a display of Tru>Steel HD drew strong interest among visitors to their booth at the Frame Building Expo in February. With the popularity of board and batten spreading rapidly, he thinks Tru>Steel HD will follow. “We had a small sample of cedar gray on our table, and it caught quite a few eyes. We had a lot of good feedback. We had a lot of people stop in, pick it up, feeling it and asking questions about it. I do think it was a hit.”

He said the company ordered a small quantity of Tru>Steel HD initially to gauge its reception. It sold out prior to the Expo, prompting them to reorder.

The product is also available through United Steel Supply that services the construction market. They are stocking four to six colors to start and have already sold out their first orders and have reordered.

What’s different about Tru>Steel HD

Switzer explained that the historical system for making designer steel used rotogravure, common in the newspaper and magazine world. Manufacturers essentially take a photo and create a pattern of art that is transferred to the steel on etched rollers. “Depending on the diameter of the roll, that pattern repeats every 29 to 31 inches,” he said, adding: “When you want to design in the true character of wood, you’re somewhat limited. If you would want to put a knot or a mark in the wood, it would repeat every 29 to 31 inches.”

Some customers wanted SDI to enter that market, but SDI saw too many disadvantages and realized that a new frontier in digital printing was evolving.

“Four or five years ago we began studying digital printing,” Switzer said. “We waited for the technology to advance before moving ahead.”

High Tech 3-D Scanners for Wood-Grain Design

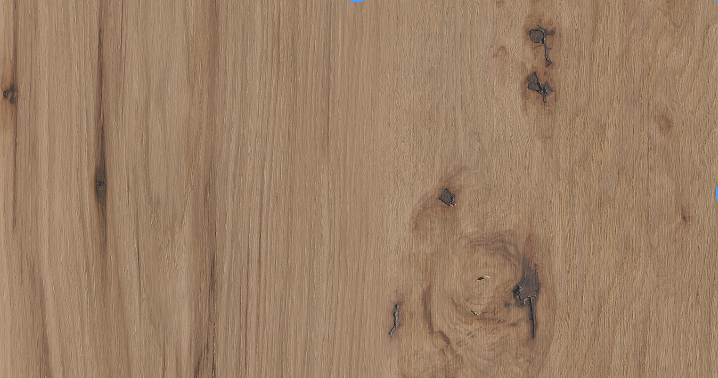

Instead of starting with a photograph, SDI’s system — which the company’s own team of experts developed — uses high tech 3-D scanners and real wood for its wood-grain designs. “It takes hours and hours to take the scan and develop that image,” he described. “Then we transfer that image and work it with our creative team, and basically form that image into a pattern our customers are looking for.”

The image can be quickly adjusted to add or delete elements of design or to adjust colors. It can run on a size range of coil from .015-.030 x 36”-60” wide. One of its best assets is that the image is repeatable over and over again without image degradation.

Unlike the rotogravure system that requires the coil to go through the process twice when color is added, the digital system allows for the change to be integrated immediately into the digital design. This also allows a single coil to accommodate multiple images.

“We thought that would provide customers a better look, that custom look they were looking for. And the [repeating pattern] would be significantly longer,” Switzer continued. “The advantage of our system is that we have up to a 32-foot repeat. That allows you to put in knots and grain and images that make the product look so much more realistic, with more depth of image … we can put knots in, we can take knots out, we can do things that really make the product very, very unique. When you etch a roll in the historical system, you’re stuck with what’s on that roll.”

Electron Beam Barrier Protection

To withstand the elements for exterior use, Tru>Steel HD is finished with an electron beam clear coat barrier protection. The paint system carries a 20-year limited warranty at this time.

SDI has developed more than a dozen stock images of wood and camouflage, including but not limited to rough sawn cedar in natural, weathered, and distressed, oak, walnut, hickory, and pecky cyprus. In the pipeline is weathered barn siding and more.

Tru>Steel HD is the first print-designed product made by a steel mill in North America. Forerunners have all been third-party. Switzer said it is a premium product but is competitive with printed steel elsewhere in the marketplace.

The current products are focused on vertical application, but SDI anticipates that roofing will follow.

Part of the charm of the new steel is that consumers can have the look of wood without some of its adverse properties, and it also ticks all the boxes for “green.” SDI makes all its steel in electric arc furnaces using at least 80% recycled steel, “so we are replacing wood, which is not recyclable, and we’re replacing it with a product that can be recycled at end of life,” he said.

In addition, the electron beam coating and curing systems developed for the process have no VOCs and related adverse environmental issues. MB

This article is from the Fall 2023 issue.