METALCON Review By Karen Knapstein

Shield Wall Media Editor

METALCON was firing on all cylinders as it opened at the Indiana Convention Center in Indianapolis. The October 12-14 event, which is produced in partnership with PSMJ Resources, Inc. and the Metal Construction Association (MCA) saw new features added for exhibitors and attendees, as well as the return of past favorites.

This is the second year the IMP Pavilion was featured at METALCON. The IMP Education Center presented Insulated Metal Panels – Installation and Handling Best Practices. During the demonstration, attendees were able to learn about best practices and common mistakes made during handling, storage, and installation of insulated metal panels.

Meet the Press

For the first time, exhibitors could meet with editors and reporters from 10 leading industry trade publications. This included representatives from Rural Builder; Metal Roofing Magazine; Rollforming Magazine; Garage, Shed & Carport Builder; and Frame Building News. Exhibitors who chose to participate spoke with media representatives about new products, newsworthy announcements, and to talk about editorial coverage. Watch the pages of your favorite trade magazines for special features and announcements.

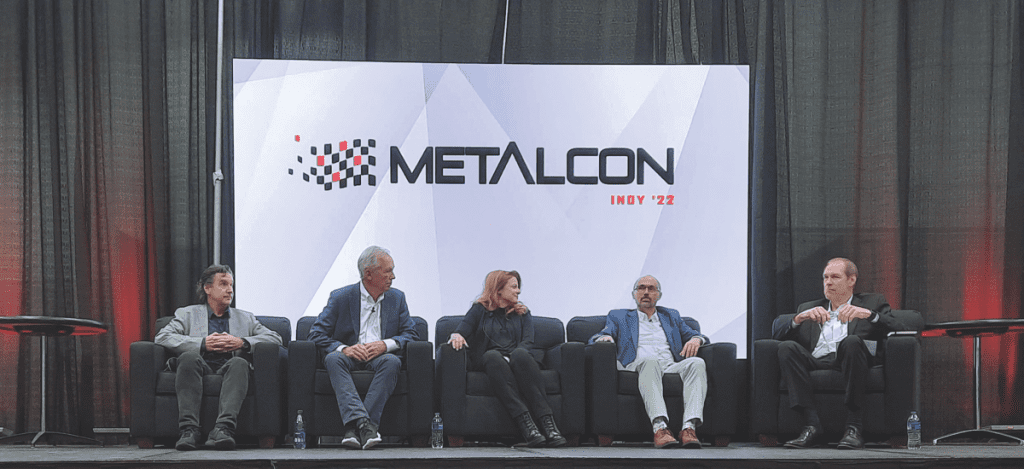

METALCON Review: State of the Industry

The State of the Industry panel, which was held on the expo floor so all could attend, was moderated by Paul Deffenbaugh, editorial director, Metal Construction News. The panel consisted of industry insiders Alan Scott, Intertek; Jennifer Heimburger, Metal Building Contractors & Erectors Association; Tony Bouquot, Metal Building Manufacturers Association; and Chuck Howard, Metal Roof Consultants, Inc.

One of the problems the panel discussed was what are the causes of supply chain problems and where do we stand now. This problem has evolved over the last couple of years; initially, the COVID shutdown caused a lack of supply. Bouquot said materials can be found now, but at higher prices. And product substitutions are sometimes necessary.

Heimburger added that, from a contractor-erector standpoint, they sometimes have to find alternate suppliers. She said it’s possible this could last a couple more years.

Pricing is always a major concern. Heimburger said that while they’ve seen steel prices increase several times over, their customers have been able to pay anyway. But, she said, we may get to the point of a slowdown because of inflation and price increases.

But price increases aren’t necessarily a deal breaker. Chuck Howard added that his company does a lot of work in the public space. Over the last two years, they “blew their budgeting.” Now they budget high, adding that money is usually found to do state projects.

All on the panel agreed that sustainability is a topic that will continue to grow in importance. Alan Scott said the sustainability trend will continue. On January 1, 2023, the “carrots are getting sweeter, and the sticks are getting bigger.” As part of the Inflation Reduction Act, the 179D tax deduction was increased and extended. He said building performance standards are pushing for existing building performance improvements and there will be huge opportunities in retrofitting.

Heimburger agrees there will be even more retrofit opportunities; it is less expensive to buy an existing building and retrofit with needed systems than it is to build new.

“There’s more demand than there is capacity,” added Chuck Howard. However, the obstacles are different. Engineering in a new building is very precise, whereas in retrofit, he said you’re trying to find out how and what an existing building is made of. Figuring out how to put a new roof over an existing one is more complicated for the contractor, but “If you get into retrofit, there will always be work to do.”

Exhibitor Feedback

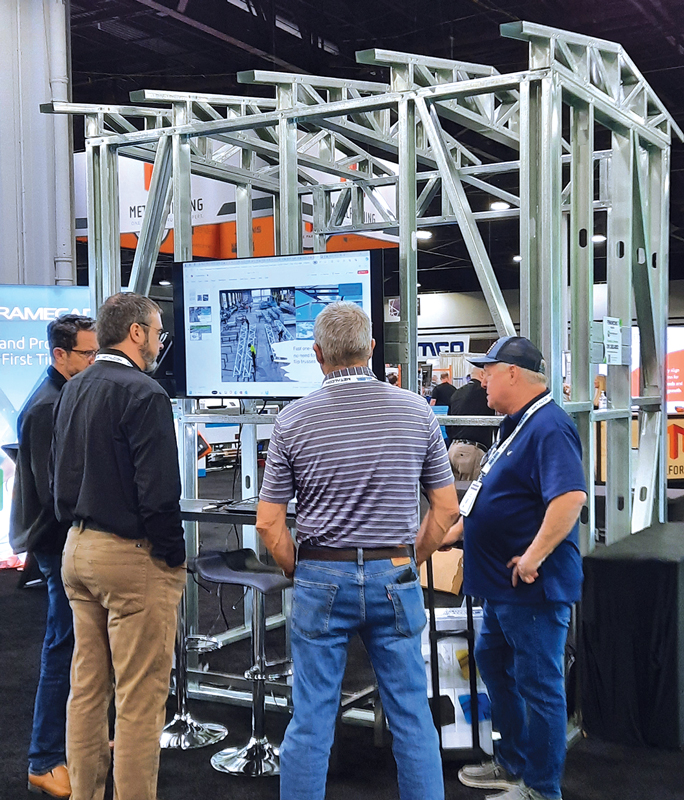

Attendees were able to connect with almost 250 exhibitors on the trade show floor. Some of them share their METALCON experience and market predictions:

“Quality Metal Stamping has been exhibiting at METALCON for over 20 years,” said Business Development Manager Colin Serling. “We think it is the premier place to connect with and learn from the top metal construction professionals in the industry. We appreciate the support and look forward to continuing our position as a valuable supplier to this industry.”

Mark Gies, S-5! Director of Product Management, had this to say: “At S-5!, our message to the industry is that metal roofs are the best place to install solar panels because of their long service life. We are seeing a growing interest in solar since the announcement of the many incentives now available through the Inflation Reduction Act, and we expect to see the metal roofing sector grow as a result.”

“We had a lot of great meetings with industry partners and got to meet a lot of new and existing customers,” enthused Scott Tomlin of D.I. Roof Seamers. “METALCON is always a good show for us.”

Direct Metals, Inc. showcased its metal roofing fasteners and accessories. “We were impressed by the quality of attendees,” said David Quehl, Director of Sales & Marketing. “The majority of those who did stop at our booth are involved in standing seam metal roofing, an area DMI specializes in. Traffic was steady the first two days and although the third day was light from an attendance standpoint, we still had good substantive discussions with those that did stop. It was good to see attendees who traveled from Alaska, Washington, Montana and Central and South America. It helped expose our company to a wider audience.”

Brian Esh, Eagle Business Software, said “METALCON is always a great venue at which to learn what’s new in the metal roofing industry and collaborate with existing customers, new leads, and business partners at the same place.”

“METALCON was a great place to catch up with existing clients and meet some potential new ones,” said Phil Costar, Managing Director, ACT Building Systems. “Within the space of two days we touched based with a number of clients that would have otherwise taken a few weeks to have called on.”

“As always, METALCON proved that we are part of a vibrant and growing industry,” summed up Todd E. Miller, President, Isaiah Industries, Inc. “The folks who visited our booth were very diverse which is always a nice thing. We had visitors ranging from property owners to sub-contractors to general contractors and architects.

“We had a lot of interest from attendees in our newer products,” he continued. “No longer is metal unique to the building envelope. It is, for many people, almost a ‘given’ but what they care about are metal products that offer unique aesthetics and also greater energy benefits.

“We are looking forward to next year’s show in Las Vegas. It’s been a few years since METALCON has been out West. The emphasis out there on fire safety and energy efficiency is daily bringing about increased specification of metal.”

Fire safety and energy efficiency will provide the basis for a great METALCON 2023. MR

Click on an image for a popup slideshow.