Atlanta Show Delivers World-Class Business Opportunities

This fall, the world’s largest metal construction show took center stage in Atlanta. The premier event, held Oct 29 to Nov. 1 at the Georgia World Congress Center, immersed exhibitors and attendees in three intense days of networking, keynote addresses, educational seminars, and hands-on demonstrations.

Exhibitors

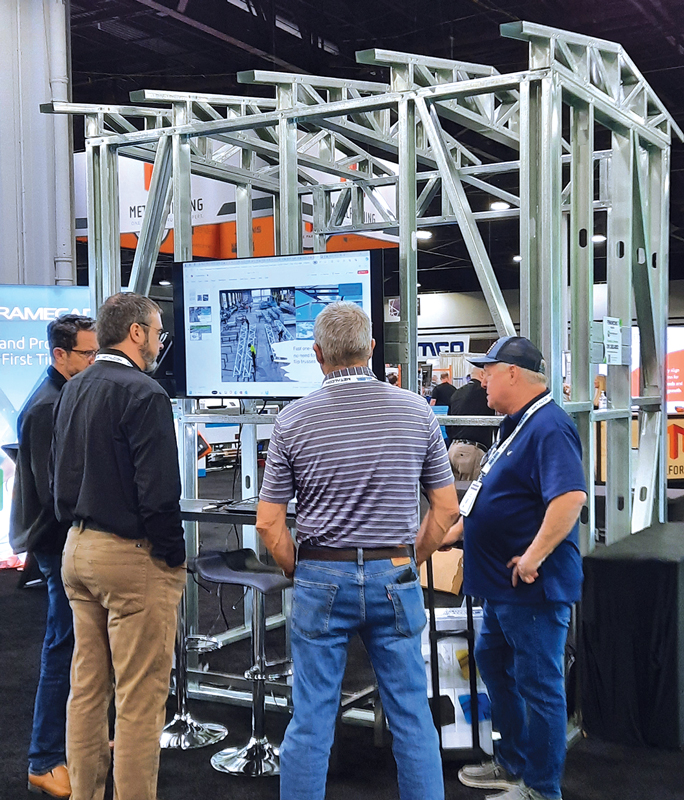

More than 200 exhibitors from over 45 countries interacted with contractors, builders, fabricators, architects, engineers, designers, and developers, presenting and demonstrating their lines, with some unveiling brand-new products and services. For example, the New Zealand-based company FRAMECAD introduced Nexa, which it describes as “the first end-to-end production management platform designed specifically for cold-formed steel framing. Nexa empowers cold-formed steel panelizers and modular builders with complete visibility and control of their operations from the factory to the jobsite.”

Seminars

Keynote speakers included former NFL MVP quarterback and Super Bowl Champion Joe Theisman, who presented a “Game Plan for Success.” in his inspiring delivery, he explained how to translate the experiences he learned on the football field — dealing with pressure, adapting to new situations, setting goals, and correctting errors — to the business world.

Economist Dr. Anirban Basu, Chairman and CEO of Sage Policy Group, presented the seminar, “The Good, The Bad & The Ugly: Financial Outlook and Trends for the Metal Construction Industry.” Dr. Basu covered topics such as the Federal Reserve’s impact on the industry, the influence of the current geopolitical conflict, the presidential elections, wages, rising consumer debt levels, high interest rates.

AkzoNobel booth.

ASC Machine Tools Inc. booth.

FRAMECAD booth.

Dr. Melissa Furman of Career Potential spoke on the topic “Relevant Leadership: Navigate, Elevate, Accelerate.” In her session, Dr. Furman discussed the distinctions between management and leadership. She explained that as organizations deal with diversity, change, and disruption, the need for skilled leaders has increased. Her seminar was geared to inspire, challenge, and equip them with practical skills needed for success.

Training

Sponsored by Sherwin Williams/ MetalVue and led by John Sheridan of Sheriden Metal Resources, the METALCON Training Zone gave attendees the opportunity for hands-on training using mock-ups and a range of materials, including painted steel, aluminum, zinc, and copper. Participants were shown how to use the proper tools and techniques to provide customers with top-notch results.

In MCA’s Metal Mastery Demo Area, presenters demonstrated techniques and best practices for forming panels and installing metal roofing systems. They also covered retrofit systems and on-site rollforming and machine maintenance.

Education

Attendees had the opportunity to attend numerous educational classes and workshops over the three days of the show. The Design District Learning Sessions were held specifically for architects and engineers, where they were introduced to innovations and cutting-edge trends.

Networking

For those who wanted to connect with others in the industry, METALCON hosted roundtables, speed networking, Future Leaders Friday, Metal and Mimosas, and Global Matchmaking.

Looking Ahead

METALCON 2025 is scheduled to be held Oct. 21-23 at the Las Vegas Convention Center, Las Vegas, Nevada.

Top Product Awards METALCON 2024

Exhibitors were invited to nominate their standout products for the prestigious METALCON Top Products Award. The top three award-winning products were determined by an electronic voting process, which took place before and during the event, with more than 1,100 votes from industry professionals.

First Place

Company: PPG

Product: PPG DuraNEXT™ Energy Curable Coil Coatings

Unlike traditional coil coating systems that require very high temperatures to drive the curing process, PPG DuraNEXT™ energy curable coatings use an electron beam or ultraviolet energy to convert a liquid coating into a fully cured solid finish in seconds, without significant loss of thickness or weight. This family of backers, primers, basecoats, and topcoats represents an alternative to traditional coil coating systems.

“We are thrilled to be recognized as the number one top product in the metal construction industry,” said Craig Smith, PPG Global Technical Platform Director, Coil Coatings. “Our innovative technologies boost productivity by eliminating the need for substrate heating and reducing curing time, as there’s no waiting for solvents to evaporate. Additionally, our products are engineered to maintain the finish durability and aesthetic appeal of coil-coated products, offering exceptional hardness, scratch, and chemical resistance, and high flexibility.”

Second Place

Company: Malco Tools, Inc.

Product: Power-Assisted Seamer/Cutter

Malco’s power-assisted seamer and cutter is ideal for effortless seaming, cutting and removal of 1” or 1.5” single and/or double mechanical lock standing-seam panels efficiently. The new seamer enables the mechanical lock of standing seam panels in less time while enhancing safety and expanding the range of compatible panel profiles. The power-assisted cutter cuts below the mechanical lock and through clips with precision, allowing for quick and safe removal of standing seam panels without damaging the cutting discs.

“Malco’s power-assisted seamers and cutters are the latest innovative, high-quality additions to our metal roofing portfolio, representing the fastest seaming and cutting machines on the market,” said Shane Norman, senior product manager at Malco. “We are honored to be recognized as a top product in the industry. These tools continue our legacy of innovation that combines state-of-the-art design with rigorous standards that have always been the hallmark of Malco products.”

Third Place

Company: MetalForming LLC

Product: Stolarczyk Coil Processing Solution

The all-new Stolarczyk Coil Processing Solution combines advanced technology, ease of use and robust performance in a single, comprehensive system. It features a Decoiler with seven-roll CNC straightening system and laser-hardened rolls to eliminate coil set and ensure flat sheets, along with a three-roll rotating film application for surface protection. The system’s Slitting-Cutting section (ST-1250) uses large-diameter slitting knives (over 8”) and a digital positioning system for precise cuts, while heavy-duty guillotine shears with four-sided blades handle length cuts. The Stacking Table automatically lowers as stack height increases, with adjustable side and end stops for alignment. The system smoothly transitions into a high-speed Tension Stand and Recoiler at up to 150 feet per minute with easy one-person operation.

“Each year, we look forward to discovering the latest technologies and innovations presented at METALCON,” said Stephen Gosk, MetalForming President and CEO. “This year, we are proud to be recognized for contributing one of the standout solutions. As a leader in coil processing, our newest Stolarczyk solution sets the standard for performance and establishes an industry-leading footprint.”

To be eligible for consideration, products must have been introduced to the market after Jan. 1, 2023, and its manufacturer a participating exhibitor at METALCON 2024.

“Following one of our most successful and well-attended shows in Atlanta, we’re excited to announce our top three product award winners,” said Judy Geller, METALCON Vice President of Tradeshows. “We can’t wait to see what next year’s showcase in Las Vegas will bring, with even more groundbreaking products and innovative technologies on display.” MB